The importance of compressed air quality in the SMT industry

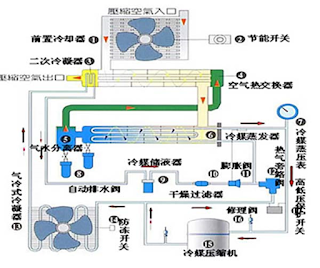

Compressed air is the second largest power source after electricity , which has been widely used in the SMT industry, such as: chip mounter of automatic multi-function, printing machine of high precision solder paste , automatic wave soldering machine pneumatic equipment etc. while many enterprises take configuration of SMT production line , equipment selection, and subsequent installation and use into consideration , which often only pay attention to the main equipment s election, ignoring the dryness and cleanliness of compressed air as a air source , it leave a long-term risks to the production assembly line . The compressed air is used in the SMT assembly line is not only required to provide stable and sufficient air pressure and flow, but also it must be dry and clean. t he air contains impurities particle such as water, oil, dust and so on. they enter the air compressor to compress a fter a simple filter ing , these solid particles and compressed air