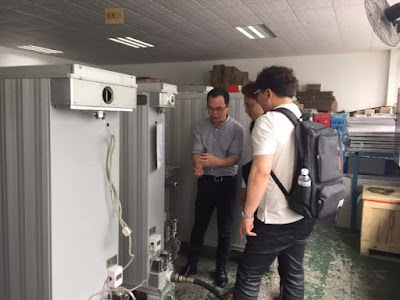

MSM Co.,Ltd Visit Biteman Again

Sep 25th, 2017, MSM Co., Ltd. General Manager and Director visit biteman headquarters from South Korean with more orders. MSM Co., Ltd. visit again after signing exclusive agent agreement at May, we can see that biteman products are in short supply in the Korean market. This visiting MSM Co., Ltd. is holding the mentality of learning, and the enthusiasm of learning and will not be far away China although a thousand miles apart. During visiting the factory, MSM Co., Ltd. propose and ask some question (what Korea end-user feedback) to Mr. GuoYinghui, who has answered one by one. As for a lot of technical problems, the biteman related technical staff gives a detailed answer. From May to September, less than four months MSM Co., Ltd still holding the mentality of learning for such long distance, we can see MSM Co., Ltd. pay attention to the biteman product. This can also be seen that Korean market has very large demand for our products. In p