Disadvantages and Causes of Refrigeration Air Dryer

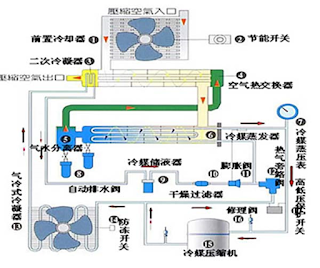

Compressed air of Humid high-temperature enter into the precooler (specific-high-temperature) , which heat flow into the heat exchanger to process heat exchange from cold air in evaporator so that the temperature of the compressed air can be reduced into the evaporator.

After the heat exchange of compressed air into the evaporator through heat exchange of the heat transfer function and refrigerant of evaporator , the heat of compressed air is taken away by the refrigerant, then compressed air quickly be cool, the moisture of moist air reach saturated temperature then rapid condensation. After condensation, the water is condensed to form water droplets, which are rotated at high speed through the gas-water separator,water is separated from the air by centrifugal force, and the separated water is discharged from the automatic drain valve. After lowering the temperature of the compressed air pressure dew point theory up to +3 ~ +10 ℃, the general measured at +20 ℃ or more.

Operating principle diagram

Disadvantages of Refrigeration Air Dryer:

1. Compressed air quality can not meet the production requirements due to limit of technical principles

2. Outlet quality is unstable, and keep liquid water without absolutely adsorbing , generally the pressure dew point is above +10 ℃

3. The use of refrigerants (contain Freon) will cause serious air pollution

4.Refrigerant compressors will consume energy about 6% when the pressure dew point +10 ℃during continuous working.

Causes:

The temperature of the refrigerant evaporation does not allow less than 2 ℃ due to its working principle and structure, , otherwise it will freeze and plug the pipe, which leads to compressed air can not pass. The principle of refrigeration air dryer determines the real outlet dew point of the gas can not reach the set value of the evaporator. Therefore, to obtain a lower dew point, the power of refrigerant compressor must be increased, which greatly increases the production cost. Moreover, the Freon generate gas in the refrigerant will destroy the atmosphere, the environment will cause great pollution.

As Survey show that most industries and pneumatic equipment require compressed air pressure dew point between -20 ℃ ~ -40 ℃, however, most of the current market dew point are between the measured 20 ℃ ~ 35 ℃, and mixed with a large number of liquid water, Greatly reducing the use life of equipment, and increase failure rate of the equipment .

When the outlet temperature of compressed air is 45 ℃, the pressure dew point is 10 ℃, the energy consumption (mainly refers to electricity) is about 6%; while the current market, penetration rate of refrigeration is high, but most brands are small processing workshop, so there is no high-end brands to guide. This is reason why refrigeration technology is falling behind manufacturing technology is low level , market requirements are not standardized .

The temperature of the refrigerant evaporation does not allow less than 2 ℃ due to its working principle and structure, , otherwise it will freeze and plug the pipe, which leads to compressed air can not pass. The principle of refrigeration air dryer determines the real outlet dew point of the gas can not reach the set value of the evaporator. Therefore, to obtain a lower dew point, the power of refrigerant compressor must be increased, which greatly increases the production cost. Moreover, the Freon generate gas in the refrigerant will destroy the atmosphere, the environment will cause great pollution.

As Survey show that most industries and pneumatic equipment require compressed air pressure dew point between -20 ℃ ~ -40 ℃, however, most of the current market dew point are between the measured 20 ℃ ~ 35 ℃, and mixed with a large number of liquid water, Greatly reducing the use life of equipment, and increase failure rate of the equipment .

When the outlet temperature of compressed air is 45 ℃, the pressure dew point is 10 ℃, the energy consumption (mainly refers to electricity) is about 6%; while the current market, penetration rate of refrigeration is high, but most brands are small processing workshop, so there is no high-end brands to guide. This is reason why refrigeration technology is falling behind manufacturing technology is low level , market requirements are not standardized .

Original Article from www.biteman.com

评论

发表评论