Common Sense of Purification Equipment

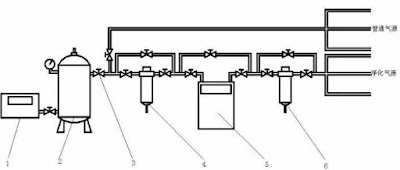

Gas source system consists of generates, processes and stores compressed air equipment. A typical air supply system consists of following components: air compressors, rear coolers, filters (including pre-filter, oil-water separator, pipeline filter, degreasing filter, activated carbon filter, sterile filter etc.), gas storage tank, dryer (refrigeration and adsorption), automatic drainage&sewage device and gas pipeline, pipeline valves, instruments and so on. It combines into a complete air supply system according to the different needs of the technological process.

Why must process air supply system?

Compressed air (output from air compressor) contains a large number of harmful impurities, it will cause great harm to the gas source system if without appropriate method to remove these impurities:

1. Degenerative lubricating oil will make rubber, plastic, sealing material deterioration, and then plug holes, resulting in valve failure, pollute products;

2. moisture and dust will cause rust corrosion of metal devices and pipeline,moving parts stuck or wear, making pneumatic components malfunction and leakage, moisture and dust will plug throttle hole or filter net, moisture freeze cause pipeline freezing or crack in cold areas;

3. The reliability of pneumatic system greatly reduces service life due to poor air quality, resulting in its loss is often much higher than air supply handling device and maintenance costs, so it's absolutely necessary to correctly choose air supply handling system.

What are the criteria for air supply quality?

Different users have different requirements on air supply quality, the national standard GB / T13277-91 of general compressed air quality level (adopting ISO8573 by equivalent) is developed for this purpose. The standard specifies the number of solid particles, moisture and contained oil in the compressed air. In a broader sense, a good air supply should be stable pressure during use, so its pollution is the smallest for surroundings environment.

What kinds of compressed air drying method?

Compressed air can remove water vapor via pressurized, cooled, adsorption and other methods, and then remove liquid water by heating, filtration, mechanical separation and other methods. Wherein refrigerated dryer cools compressed air temperature to remove contained water vapor, while adsorption dryer removes water vapor in the compressed air by adsorption, thus obtaining a relatively dry compressed air.

评论

发表评论